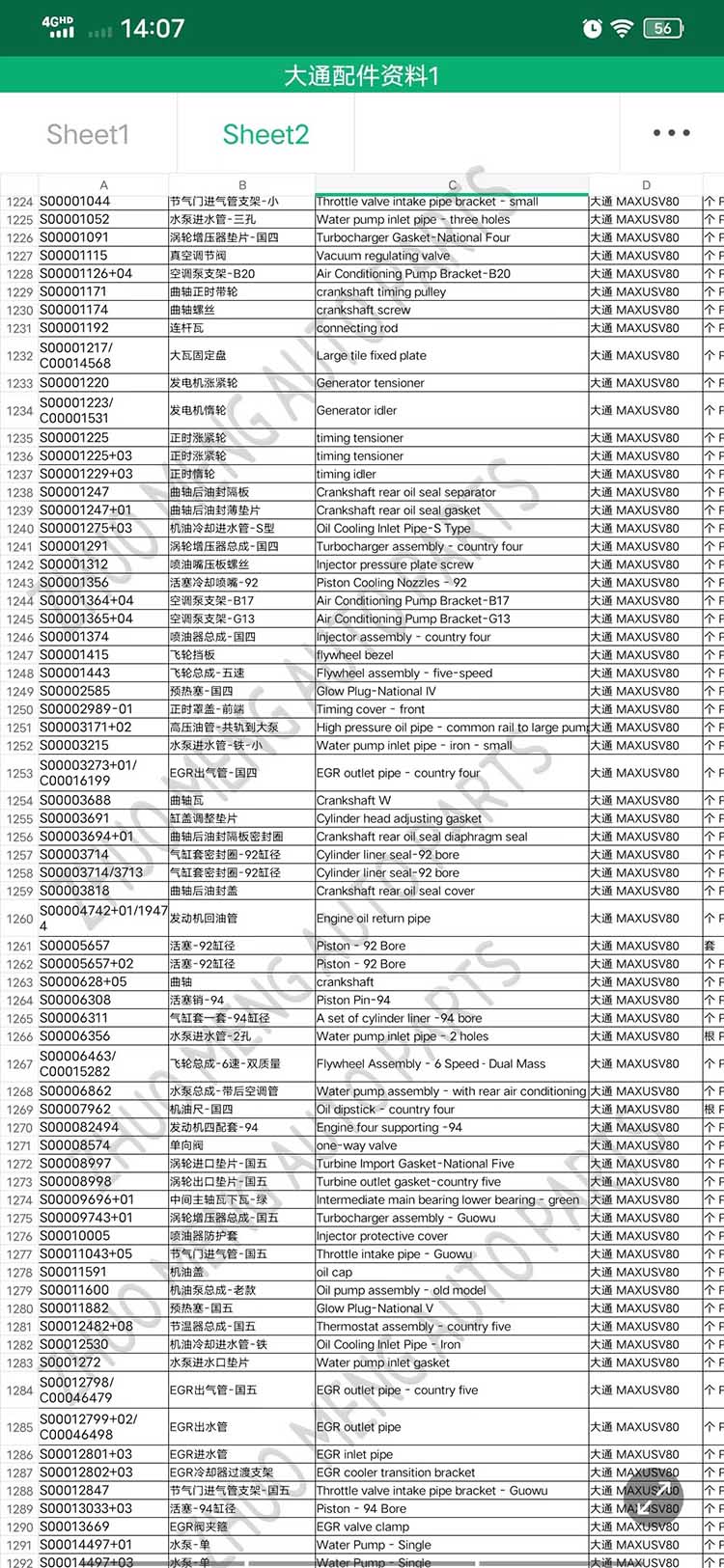

Pretio officinae SAIC MAXUS V80 tegumentum ornatus ferriviae ostii medii

Descriptio Brevis:

Detalia Producti

Etiquettae Productarum

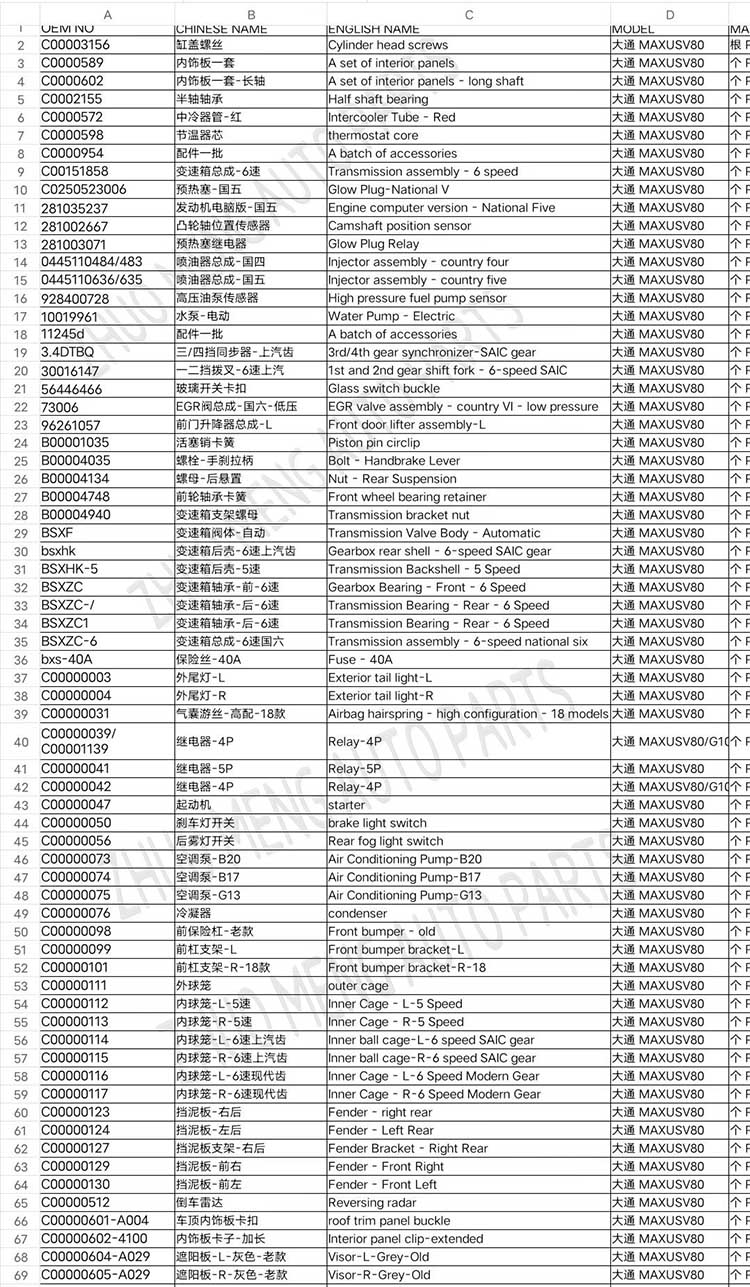

Informationes de productis

| Nomen productorum | Operculum ornatus ferriviae labentis ianuae mediae |

| Applicatio productorum | SAIC MAXUS V80 |

| Producta OEM NO | C00004327 |

| Ordo loci | FACTUM IN SINA |

| Nota | CSSOT /RMOEM/ORG/EXEMPLAR |

| Tempus praescriptionis | Copia, si minus 20 PCS, normalis unus mensis |

| Solutio | Depositum TT |

| Nota Societatis | CSSOT |

| Systema applicationis | Systema frigidum |

Scientia productorum

1. Exemplar utilitatis ad campum technicum ianuarum autocineticarum pertinet, praesertim ad structuram fulcrum operculi ferriviae labentis mediae ianuae labentis.

Ars secundaria:

2. Hodie, pleraque vehicula mercatoria vel raedae porta media labili instructa sunt, et vectes labiles in porta media labili plerumque in lamina exteriori parietis lateralis corporis dispositi sunt. Ad vectem labilem portae mediae labilis instituendam, necesse est sulcum praebere cuius longitudo in directionem anteriorem et posteriorem corporis vehiculi extendatur in superficie laminis lateralis corporis et infra vitrum laterale posterius, et vectem labilem portae mediae labilis in sulco collocari. Cum vectis labilis portae mediae labilis directe laminae exteriori parietis lateralis exposita sit, facile pulvis accumulatur et a pluvia eroditur dum vehiculum utitur, quod efficit ut cylindrus cardinis portae labilis non leniter labatur, quod portam labilem claudit et chartam emittit. Quapropter, operculum plerumque adhibetur. Lamina ad vectem labilem portae mediae labilis tegendam ut propositum assequatur vectem labilem portae mediae labilis celandi.

3. Attamen, operculum exstans plerumque clavis et nucibus ad latus externum affigitur. Postquam operculum fixum est, reliquae partes interiores tandem in curru collocantur (modus remotionis omnino contrarius est). Lamina operculi vectis labentis ianuae mediae labentis occultatur, et difficile est eam claudi et removere dum installatur. Deinde, forma operculi reservata in lamina exteriori parietis lateralis facienda est. Si lamina operculi tollitur, species laminae exterioris parietis lateralis graviter afficietur et qualitas aspectus totius vehiculi minuetur. Simul, nonnulla exempla laminam operculi non requirunt, ergo non opus est formam laminae operculi in lamina exteriori parietis lateralis reservare. Propterea, lamina exterior parietis lateralis duas specificationes habet, quae non solum sumptum aperiendi laminam exteriorem parietis lateralis augent, sed etiam administrationem partium non facilitant.

Elementa implementationis technicae:

4. Ob defectus artis prioris supra memoratos, problema technicum hoc exemplo utilitario solvendum est: quomodo structuram institutionis laminae operculi vectis labentibus ianuae mediae praebere, ut processus institutionis laminae operculi existentis ad vectes labentes medios ianuae labentes occultandos melior fiat. Difficilius est claudere et removere, et commodum est alternare inter praesentiam laminae operculi et praesentiam, nec opus est formam laminae operculi in lamina exteriori parietis lateralis reservare.

5. Ad problema technicum supra dictum solvendum, exemplar utilitatis hoc schema technicum adoptavit:

6. Structura institutionis operculi labentis ianuae mediae labentis, comprehendens laminam exteriorem parietis lateralis, corpus labentis horizontaliter in lamina exteriori parietis lateralis positum, et laminam operculi ad corpus labentis protegendum, secundum superficiem superiorem corporis labentis. Plures partes prementes verticaliter connectuntur intervallis uniformibus in directione longitudinis, et foramina positionis et foramina fasciae in superficie cuiusque partis prementes aperiuntur; lamina operculi constat ex duabus sectionibus, prima pars laminae operculi structuram rectangularem testae habet, et secunda segmentum structuram trapezoidalem testae similem habet, unum extremum primi segmenti laminae operculi introrsum curvatum est ad formandam partem curvam, alterum extremum primi segmenti laminae operculi fixe connectitur cum secundo segmento laminae operculi, et superficies interna primi segmenti laminae operculi fascia installata est. Sunt fibulae positionibus foraminum singillatim respondentes, et fibulae prope partem curvam dispositae sunt; Columna positionis, positioni unius e foraminibus positionis respondens, in superficie interna primae sectionis laminae operculi collocatur, et diameter columnae positionis diametro foraminis positionis congruit et in foramen positionis inseritur, ut motus sursum et deorsum, antrorsum et retrorsum laminae operculi limitetur; fibula in superficie laminae exterioris parietis lateralis in directione extensionis corporis ferri labentis sudatur, et sectio transversalis fibulae structuram Z formae habet, et superficies interna secundae sectionis laminae operculi fibula instructa est. Positio parti prementi respondet, et pars prementi formam laminae arcuatae habet, ita ut secunda sectio laminae operculi poni possit inserendo partem prementi per fibulam.

7. Praeterea, pars adfixionis superficiei corporis ferriviae labentis adhaerens intervallis horizontalibus in superficie interna primae sectionis laminae operculi praebetur.

8. Praeterea, impletio in superficie interna secundae sectionis laminae operculi praebetur, ut secunda pars laminae operculi per impletionem arcte cum lamina laterali externa coniungatur.

9. Praeterea, impletio est spongia.

10. Praeterea, prima pars laminae tegminis et secunda pars laminae tegminis integraliter per iniectionem formantur.

11. Praeterea, plures bloci prementes in eadem linea horizontali siti sunt, et positio fibulae inferior est quam linea horizontalis.

12. Praeterea, extremum columnae positionis a lamina operculi axilla ut conum ductorem formes.

13. Comparatis cum arte priori, effectus utiles huius exemplaris utilitatis sunt:

14.1. In hac inventione, lamina operimenti et lamina exterior parietis lateralis methodo prehensionis fixantur, quae methodum prehensionis existentis mutat, nec simul formam laminae operimenti in lamina exteriori parietis lateralis servare debet. Dum installatur, fibulae in lamina exteriori laminae lateralis in partem prehensionis inserendae sunt. Postquam prehensio in loco est, columna positionis foramen positionis spectans manebit. Laminam operimenti preme ut fibulae in foramina laminae inserantur, et lamina operimenti et lamina exterior laminae lateralis perficientur. Lamina fixa est, quod difficultatem installationis minuit. Dum removetur, lamina operimenti trahitur ut fibula a foramine laminae solvenda sit, id est, removendo laminam operimenti completa est, et remotio laminae operimenti facilis est.

15.2. Una ex fibulis (fibulis) ad tegumentum inventionis praesentis instituendum adhibitis in lamina exteriori parietis lateralis collocata est, reliquae autem in railibus labentibus collocantur. Cum tegumentum instituendum non est, lamina exterior parietis lateralis et rail labens tolluntur. Commodum est inter cum et sine tegumento alternare, nec necesse est laminam exteriorem parietis lateralis separatim designare cum tegumentum adsit, quod sumptum fabricationis laminae exterioris parietis lateralis minuit.

Descriptio delineationum

16. Ut propositum, schema technicum et commoda exemplaris utilitatis clariora fiant, exemplar utilitatis infra fusius describetur una cum delineationibus adiunctis, ubi:

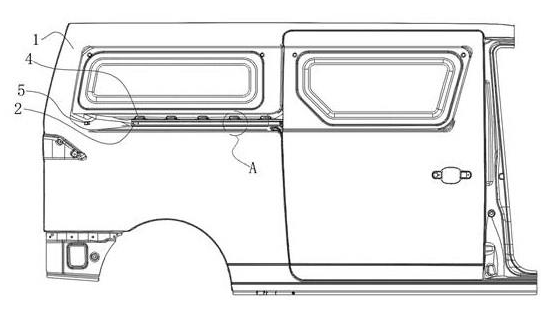

17. Figura 1 est diagramma schematicum structurae totius huius exemplaris utilitatis;

18. Figura 2 est diagramma schematicum postquam lamina operculi in Figura 1 sublata est;

19. Figura 3 est prospectus schematicus amplificatus loci in Figura 2;

20. Figura 4 est diagramma structurae schematicae laminae operculi in exemplo utilitario.

21. In figura: lamina exterior parietis lateralis 1, corpus ferriviae labilis 2, lamina operimenti 3, trabs prehendens 4, pars flexuosa 31, fibula 32, columna positionis 33, pars prehendens 34, pars adhaerens 35, foramen positionis 41, taenia, foramen formatum 42, fibula 5.

Modi accurati

22. Exemplar utilitatis praesens infra fusius describetur una cum delineationibus adiunctis.

23. Ut in Figuris 1 ad 4 demonstratur, structura institutionis operculi labentis ianuae mediae labentis in hac forma specifica includit laminam exteriorem parietis lateralis 1 et corpus labentis 2 horizontaliter in lamina exteriori parietis lateralis positum, et laminam operculi 3 ad corpus labentis protegendum, plures partes prehendentes 4 verticaliter in superficie superiori corporis labentis intervallis aequalibus secundum directionem longitudinis connectuntur, et superficies cuiusque partis prehendentis foramine positionis 41 et foramine fasciae 42 praedita est; lamina 3 ex duabus sectionibus constat. Prima sectio laminae operculi structuram rectangularem testae similem habet, et secunda sectio laminae operculi structuram trapezoidalem testae similem habet. Unum extremum primae sectionis laminae operculi introrsum curvatur ad partem curvam 31 formandam ad corpus labentis flectendum. Alterum extremum primae sectionis laminae tegminis firmiter cum secunda sectione laminae tegminis coniungitur, et superficies interior primae sectionis laminae tegminis fibulis 32, quae positionibus foraminum laminae 42 singillatim respondent, inseritur, fibulis autem prope partem curvam dispositis. Libertas laminae tegminis secundum directionem y (hoc est, latitudo corporis vehiculi) limitatur fibulis in lamina in foramina laminae insertis. Ut libertas laminae tegminis secundum directionem x (hoc est, directio anterior-posterior corporis vehiculi) et gradus libertatis secundum directionem z (hoc est, directio sursum et deorsum corporis vehiculi) limitentur, columna positionis 33, positioni unius foraminum positionis respondens, in superficie interiore primae sectionis laminae tegminis praebetur. Diameter columnae diametro foraminis positionis congruit et in foramen positionis inseritur ut libertates directionis x et z laminae tegminis limitentur. Fibula 5 superficiei laminae exterioris 1 parietis lateralis, secundum directionem extensionis corporis ferri labentis, ferrata est. Sectio transversalis fibulae structuram Z habet. Superficies interior secundae sectionis laminae operculi parte fibulae 34, positioni fibulae respondente, praedita est. Pars premens formam laminae arcuatae habet, ita ut secundum segmentum laminae operculi, parte premente in partem prementem inserta, in directionem x poni possit.

24. In hoc exemplo utilitario, lamina operculi et lamina exterior parietis lateralis per nexum rapidum fixae sunt, quod fixationem laminae operculi existentis mutat.

Non necesse est formam laminae tegminis in tabula exteriori parietis lateralis servare. Dum instituis, fibulae in tabula exteriori lateris in partem prehensionis inserendae sunt. Postquam prehensio in locum suum fixa est, columna positionis foramen positionis spectans manebit. Laminam tegminis preme ut fibulae in foramina laminae inserantur, et lamina tegminis et tabula exterior lateris perficientur. Lamina fixa est, quod difficultatem institutionis minuit. Dum dissolvitur, lamina tegminis trahitur ut fibula a foramine laminae solvenda sit, id est, dissolutio laminae tegminis perfecta est, et remotio laminae tegminis facilis est.

25. Fibulam in lamina exteriori lateris et firmitatem in rail labendi colloca. Cum laminam tegumenti non opus est instituere, fibulam firmitatis in lamina exteriori lateris et rail labendi removere potes, quod commodum est sive tegumentum adsit sive non. Commutatio inter laminas necessitatem separatim designandi laminam exteriorem lateris cum lamina tegumenti adsit tollit, ita sumptum fabricationis laminae exterioris lateris minuendo.

26. Speciatim, prima pars laminae tegminis et secunda pars laminae tegminis integraliter per injectionem formantur.

27. Ut insertio columnae positionis 33 in foramen positionis 41 facilior fiat, extremitas columnae positionis a lamina operculi remota bisellatur ut conum ductorem formet.

28. Referens ad Figuram 4, postquam lamina operculi 3 fixa est ad corpus ferriviae 2 tegendum per compressionem, ut stabilitas laminae operculi cum compressa est et non laxa servetur, pars adhaerens 35 superficiei corporis ferriviae adhaeret. Hoc modo, pars adhaerens superficiei ferriviae mediae durante installatione adhaeret, ut stabilitas laminae operculi cum compressa est servetur.

29. Ad Figuram 2 spectans, ut stabilitas laminae operculi cum comprimitur ulterius confirmetur, plures fulcra comprimientia 4 in eadem linea horizontali collocantur, et positio fibulae 5 in lamina exteriori parietis lateralis 1 inferior est quam linea horizontalis. Hoc modo, prima pars laminae operculi et iunctura premantā corporis ferri labentis, et secunda pars laminae operculi et punctum insertionis laminae exterioris parietis lateralis inter se male alignantur, et installatio premantā laminae operculi stabilior fit.

30. Ut contactus artus inter secundam partem laminae tegminis et tabulam exteriorem parietis lateralis fiat, exemplar utile etiam impletione in superficie interiore secundae partis laminae tegminis praebetur, ut secunda pars laminae tegminis et tabula exterior parietis lateralis arcte per impletionem glutinosa teneantur, ne hiatus inter utrumque relinquantur. Impletio spuma, spongia, vel similis esse potest.

31. Denique, notandum est exempla supradicta tantum ad illustrandas solutiones technicas huius exemplaris utilitatis adhiberi, nec ad limitationem esse. Quamquam hoc exemplar utilitatis descriptum est cum relatione ad exempla praelata huius exemplaris utilitatis, tamen periti in arte intellegere debent varias mutationes formae et singularum rerum ibi fieri posse sine discessione a spiritu et ambitu inventionis praesentis, ut definitum est per adiunctas postulationes.

EXHIBITIO NOSTRA

Producta similia

Producta similia

-

Pretium officinae SAIC MAXUS V80 C00014643 Turbocha...

-

Virga sustentationis cuculli originalis SAIC notae...

-

Cardines Ostii SAIC SINISTRI DEXTRI C00001351 C000...

-

Pretium officinae SAIC MAXUS V80 Calefactoris anterioris exitus...

-

Alveus lutulentus vitreus ianuae anterioris originalis SAIC...

-

Venditur directe ab officina SAIC MAXUS V80 C00014713 Pi...